Invited Speaker---Dr. Jie Yin

Associate Professor of advanced carbide ceramics group, Shanghai Institute of Ceramics, Chinese Academy of Sciences (SICCAS), China

Biography: Dr. Jie Yin is currently an associate professor in Shanghai Institute of Ceramics Chinese Academy of Sciences (SICCAS). He received his Ph.D. degree in 2013 from University of Chinese Academy of Sciences. He has been awarded Fund Programs for the Scientific Activities of Selected Returned Oversea Researchers by Ministry of Human Resources and Social Security, Youth Innovation Promotion Association of Chinese Academy of Sciences, and NSFC et al. He published more than 30 research papers in peer-reviewed journals, eg. Scripta Mater., J. Eur. Ceram. Soc., Mater. Sci. & Eng. A., including 24 as first/corresponding authors. His current research interests are development and service behavior of novel (Ta,Hf)C-based ultra-high temperature ceramic composites and their multi-scale characterizations, as well as high-performance polymer-derived ceramics.

Speech title: Effect of SiC precursors and modification of slurry infiltration for the PIP process of SiC

f/SiC composites

Abstract: SiC

f/SiC ceramic matrix composites (CMC) are considered as promising structural as well as functional candidates for potential usages in several strategic engineering applications. In the current work, SiC

f/SiC were fabricated by seven repeated polymer impregnation and pyrolysis (PIP) cycles using three types of polycarbosilane (PCS) precursors. SMP-10 had the highest ceramic yield 81.7% and the lowest melting temperature (room temperature). The CMC prepared using these precursors had high relative density and strength. Owing to the fiber pull-out mechanism during fracture, the stress-strain curves displayed a jagged failure behavior. Maximum four-point bending strength of 305 MPa was obtained from the CMC made with the NaBond precursor. Several evidences were given to reveal the strength deterioration of the NaBond-CMC material at 1500

oC in Ar atmosphere.

The slurry infiltration process of SiC

f/SiC ceramic matrix composites (CMC) prepared via precursor infiltration and pyrolysis (PIP) process was improved. Several intermediate steps for promoting the infiltration of SiC slurry into fiber fabrics, such as the spreading of fiber-fabrics by sonication, popping, electrophoretic deposition (EPD), vacuum infiltration and cold isostatic pressing (CIP), were applied before PIP process in order to improve the infiltration of SiC slurry between plane-woven SiC fiber fabrics. The intermediate processes, especially popping and CIP, had beneficial effect for increasing the green density and improving the homogeneous infiltration of the slurry into fiber fabrics. The density of the SiC

fiber/SiC

filler green body was 2.28g/cm

3, which corresponded to 68% of relative density. The SiC

f/SiC composite has a high density of 2.65 g/cm

3 after 7 PIP cycles.

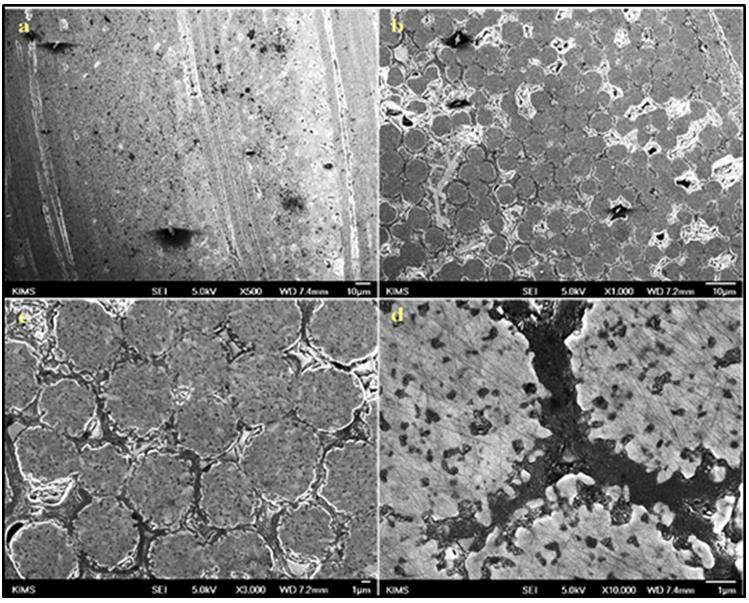

Figure 1. Density as a function of PIP cycle, and the mechanical behavior of SiCf/SiC CMCs

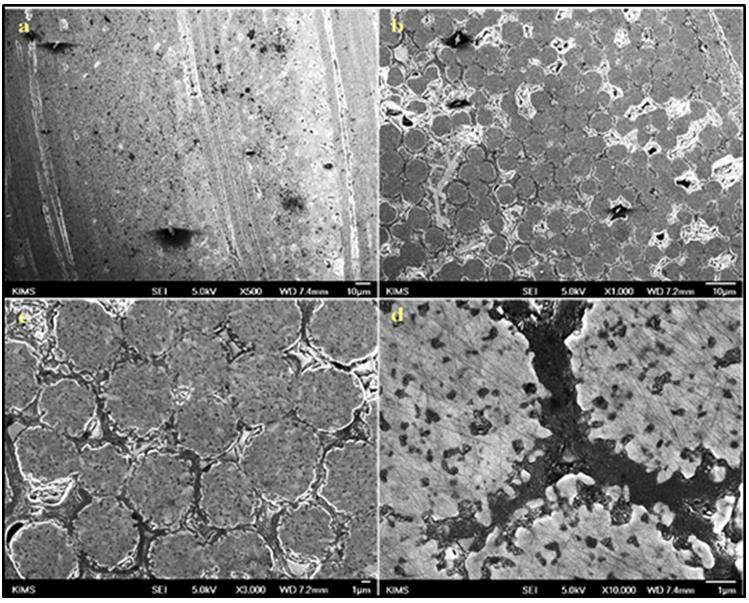

Figure 2. SEM images of polished SiCfiber/SiCfiller/SiCmatrix composite after seven cycles of PIP